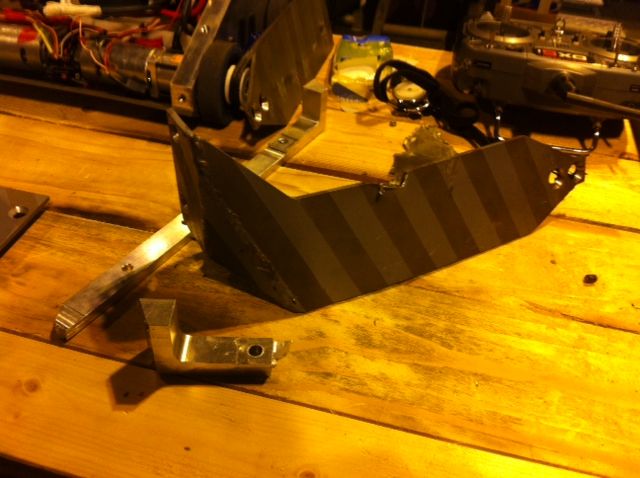

Don't trust CAD; I weighed everything in Mr Mangle down to .1 grams and its still 50 grams from the real weight. Unless you modelled every cable tie and solder joint, CAD is just an educated guess. Excellent video BTW, C3 is looking very threatening! Does it drive inverted?

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 16:10.

Reply With Quote

Reply With Quote

Bookmarks