*This is also posted in wanted section, but post also includes FeatherW questions. Apologies for double post.*

Hi there, my names Jon. This is my first post on these forums, but as long time browser though i've read and learnt allot of really useful tip and tricks already from this site and would like to take chance to say thank you for the wealth of information stored here and the willingness of users to provide it.

Back to the post, i'm a final year student studying at brighton uni. one of the projects i'm working on this year is the design and production of a Feather weight fighting robot, its run by Ian Watts, whose one of our lecturers as well, best lecture i've had at the uni.

Weapon

Were looking to make a crusher, and are having difficulties sourcing a liner actuator. at the moment were still in the design stage so were open to suggestions on spec, (around say a 100-150mm stroke, low weight with decent pushing power), however were going to have to make a decision pretty sharpish. I've found several on ebay however they tend to be completly the wroung spec, I have spoted one today that is close (15mms 800n 100mm stroke), however after contacting seller he wont sell direct, so i'm going to have to bid. Was hoping someone may have one for sale or know of a company that sells cheap items. We really cant affort to pay £80 which is what ive been quoted for the linak la22.

Power

I have a 30v drill bat that were going to cannibalize to power the weapon along with the 18v drill batteries. However would there be a way to combine the batteries for the drive and the actuator? or would this have detrimental effects on drive while the weapon was in use? Also how would the voltage normally be controlled if it is possible to combine power source.

Drive

we've sourced some cheap 18v drills from ironmongreyonline.com, but were in need of some wheels. would the suggested Robo Challenge €˜Blue wheels€™ still be the best choice?

Electronics

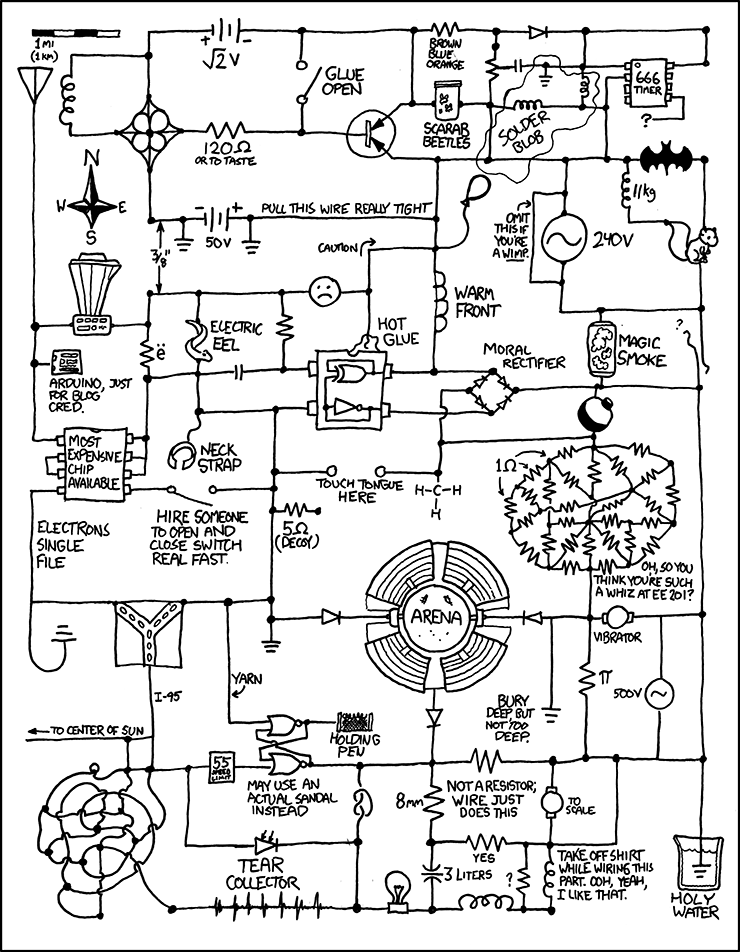

the RC unit is provided by the uni, however we need to either make the motor controller or we can buy one. Would anyone have a circuit diagram for one? my apologies if its already posted i had a look but couldn't find one. also would it be best to integrate the weapon into the same controller as drive or use a separate one?

for the body were thinking of using a tubular steel frame with a thin 1mm welded plate shell.

If anything i've suggested sounds stupid or wishful thinking please pull me up on it. I built an ant weight about 5 years ago for school, but its not that relevant to this build.

Thank you sincerely four your time =)

Jon A

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 17:43.

Reply With Quote

Reply With Quote

Bookmarks