- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 15:16.

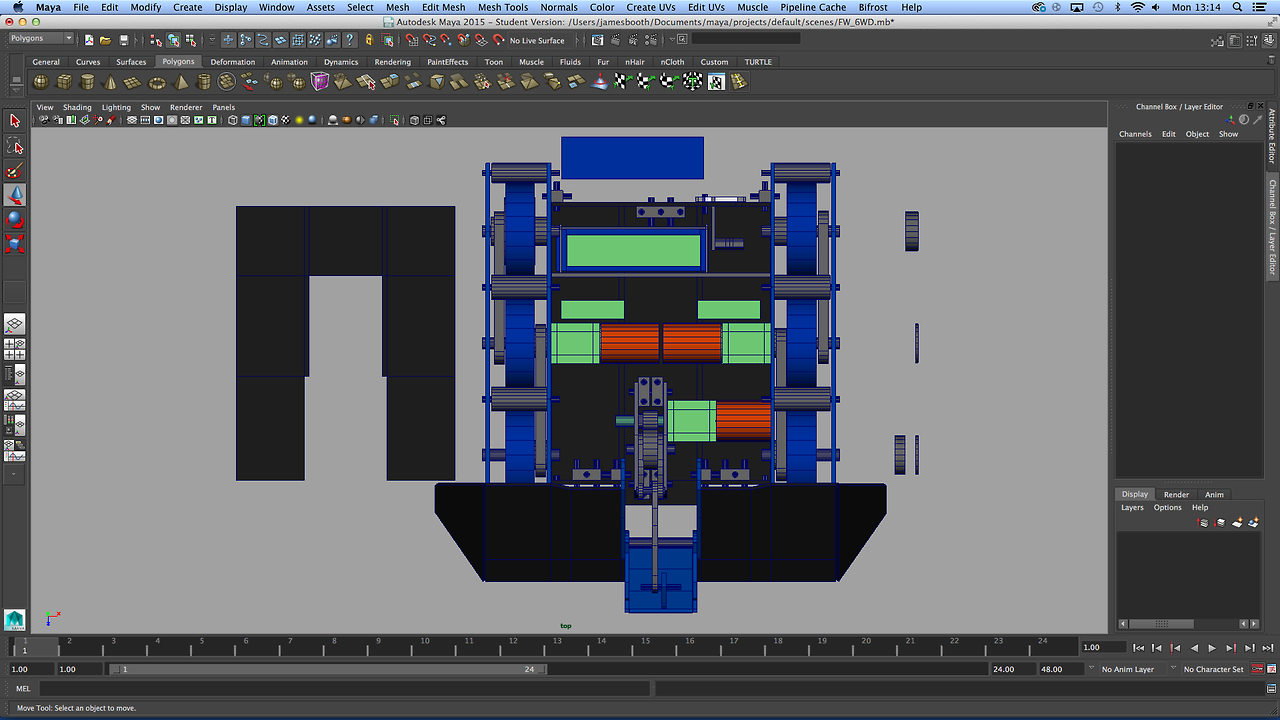

A top down view of the tight fit for the motors, plus the battery has a it's foam and holder. Adjusted the wheels slightly.

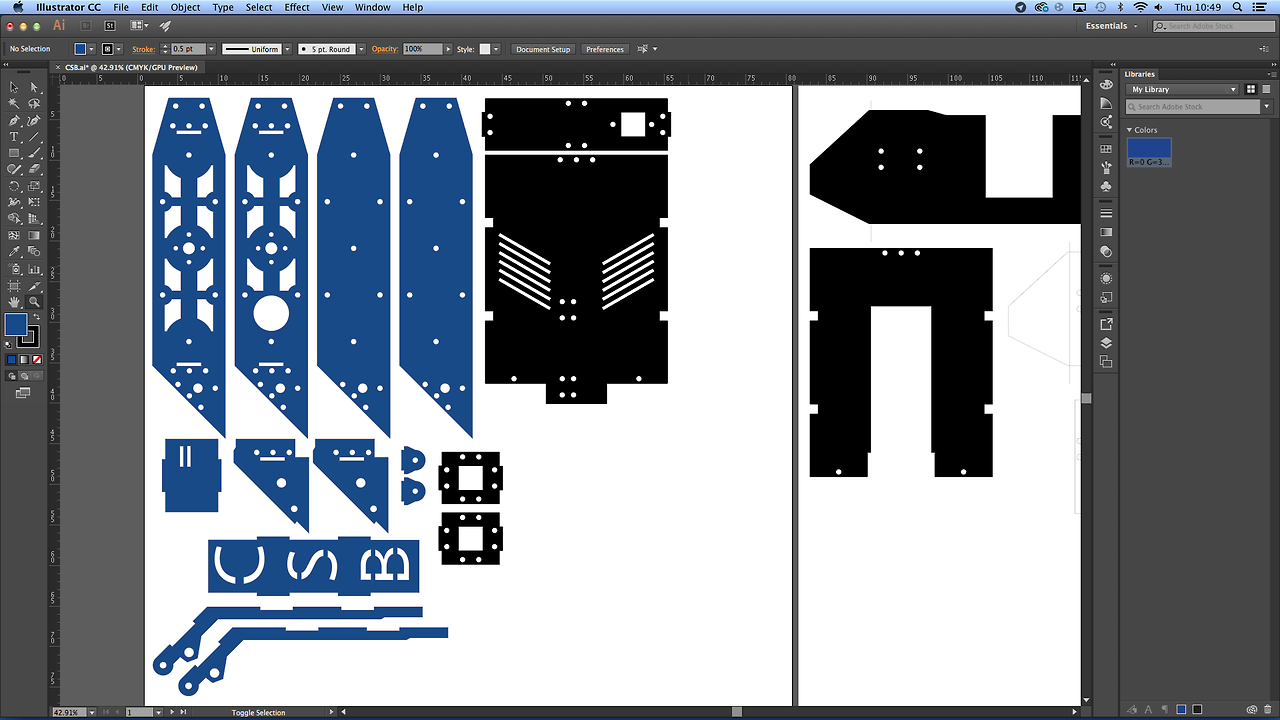

Refined the design of the parts in 2D.

I think you should do this instead of Wolf-E. All you need is a beefy motor and gearbox with an accompanying ESC and you have yourself a, by the looks of it, much better looking machine. Or you could still do Wolf-E if you have reliability in mind.

Well I am considering it but if I choose to work on CSB instead of Wolf-E I'll end up wasting the Drill motors and brushed ESCs as CSB is designed to be brushless. Plus I could do with getting some experience with the weight class first and Wolf-E is a basic machine to get my head round things.

Been working on the wedge of CSB's design and reached a head-scratcher. What material should I use on for the wedge so that it can be countersunk so the bolts are flush?

And what would be the best way to achieve the 45 degree angled sides to the wedge? I don't know if it can be done by bending a single part or simply have it in 3 parts and welded them together.

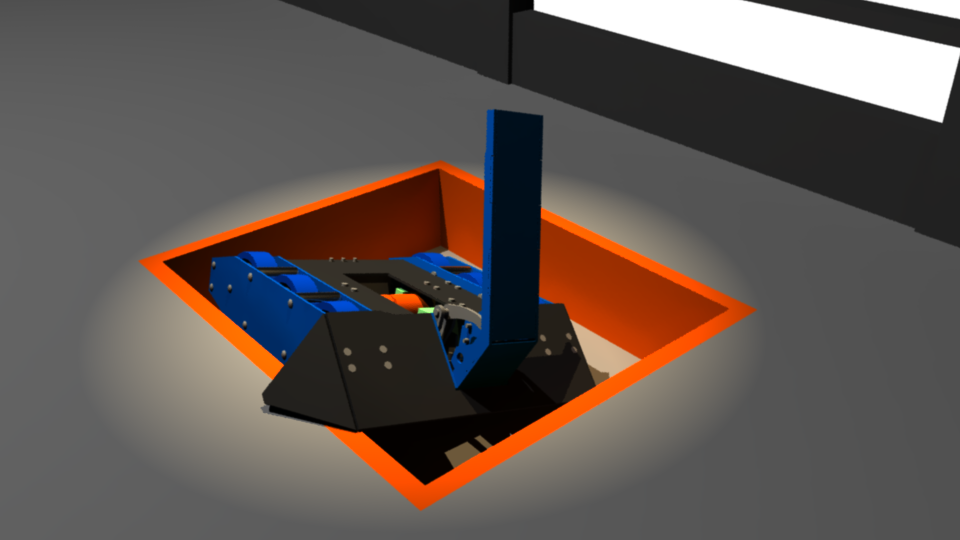

Oh and almost forgot this little render I did for a laugh

I would have thought it would be stronger as a single piece formed into the three angles rather than a three piece wedge.And what would be the best way to achieve the 45 degree angled sides to the wedge? I don't know if it can be done by bending a single part or simply have it in 3 parts and welded them together.

Team Kaizen - Build Diary for all the robots

AW: Amai, Ikari, Lafiel, Osu, Ramu

BW: Shu!, The Honey Badger

FW: Azriel

MW: Jibril, Kaizen

It can be bend 180°, but with the right radius. Hardox will break if bend too sharp.

You can find the working instructions here.

https://www.ssab.com/download-center...ormi&dcSearch=

Bookmarks