Precision engineering hour!

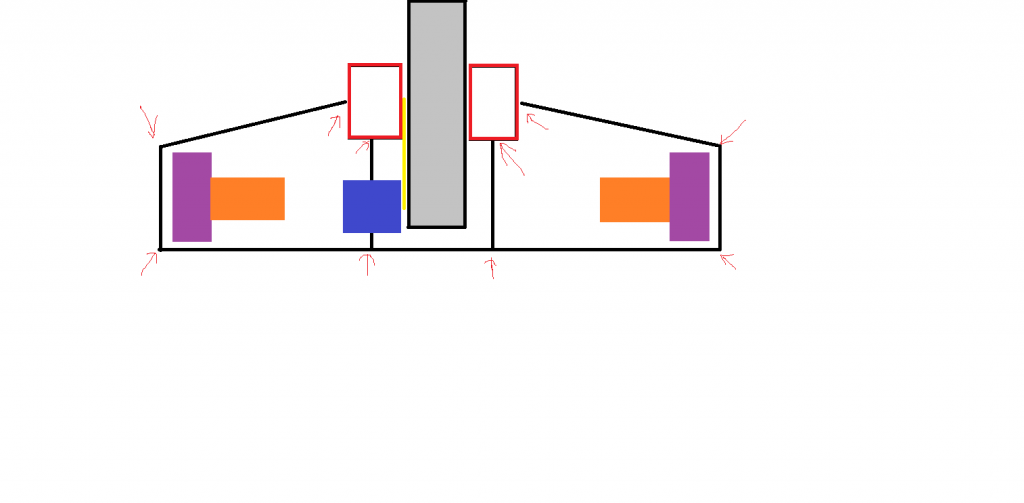

Quick design question for anyone who has experience with beefy vertical spinners, when I'm looking at wheel placement, where about should they go? As a VERY rough sketch of the planned layout (minus batteries and escs) this is the sort of thing I'm going for, bar's 400mm high, body of the machine, probably about 150mm high all the way round. That's what the wheels will roughly be anyway, so that's something to base it on...

Red = mild steel (3mm wall)

Red arrows = weld points

Blue = brushless motor (weapon, probably some NTM 5060)

Orange = drive motors/gearbox

Purple = Wheels

Black = Hardox, 3.2mm

Silver = bar, definitely not proper dimensions

Right, so here's the rest of the 20 questions haha

Should the wheels poke out of the back? I'd like to say yes for mobility reasons, but at the same time it concerns me a little that it'd ruin the structural integrity of the machine.

Would 3.2mm hardox be alright for the job? Demon runs a similar setup to this, but I believe that uses thicker steel... I'd hate to think it's too thin on that front and I'm going to end up twisting the entire chassis after one hit, if not - would 5mm be more suitable, or a higher grade even?

I've got a few welds on the robot, would it be better to weld that back plate on all 4 points, or bolt on for the support bulkhead type things running through the middle? I'd worry about over-welding it, but I don't know if the support is needed... I do have a fixed shaft for the bar though, so that might help too...

Finally, stability - would this sort of design be too top heavy to accommodate a 400mm bar? The bulkheads would reach probably something like 200-240mm tall, and let's say 430mm tall with the bar upright - whilst this sort of design would mean it's a lot wider so better for stability when turning, I don't know if it'll end up being too top heavy and knocking itself over too much...

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 07:47.

Reply With Quote

Reply With Quote

Bookmarks