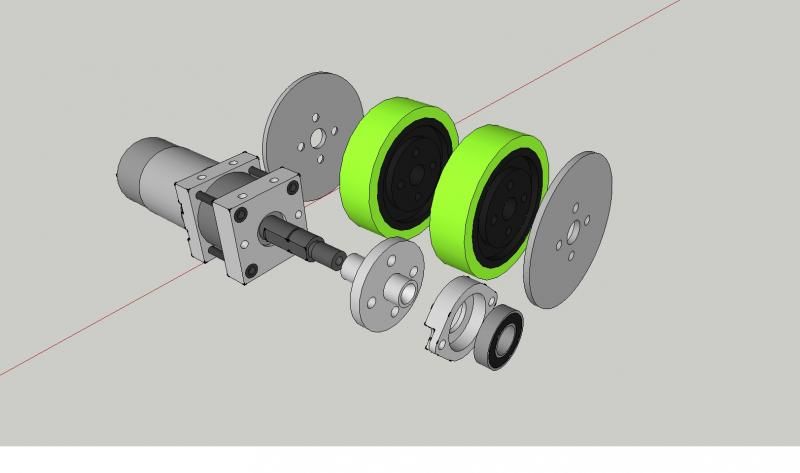

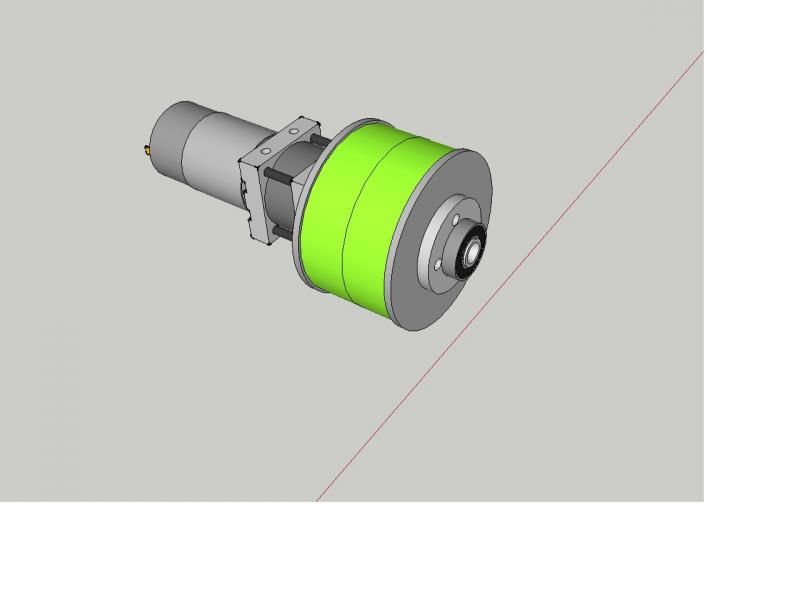

Thanks :wink: The wheels I planned to use are twin 73x20mm banebots to give me a with of 40mm.

Like this:

http://www.technobotsonline.com/banebot ... re-30.html

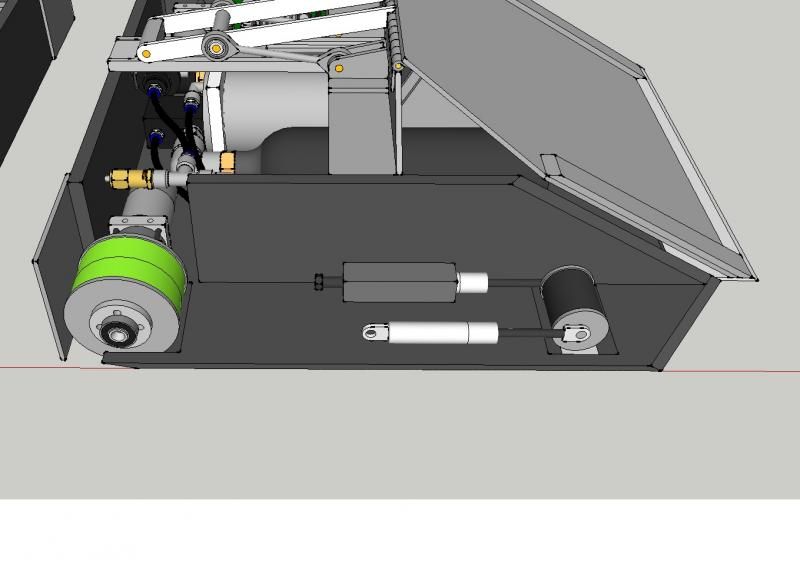

But the drive system will be different from what's in the drawings... I'm still obsessed with having it track driven!

I know it was a real pain to set it up and it was not the most efficient drive system at all - but I designed a new set up which hopefully should work...the steady bearing on the gimson motors will come in handy for this!

Will post a couple of drawings tomorrow...

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 09:18.

Reply With Quote

Reply With Quote

And again, great CAD! An exploded drawing in Sketch-up!

And again, great CAD! An exploded drawing in Sketch-up!

Bookmarks