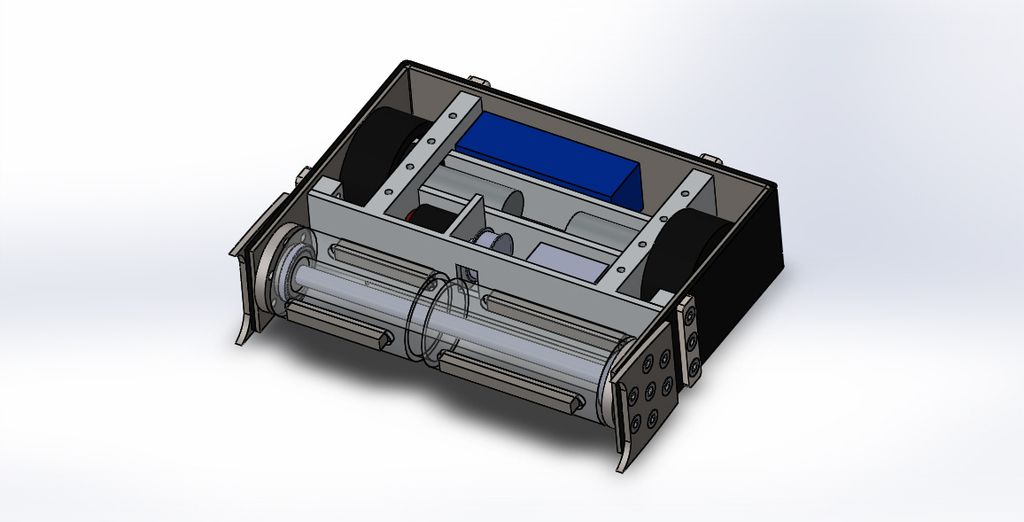

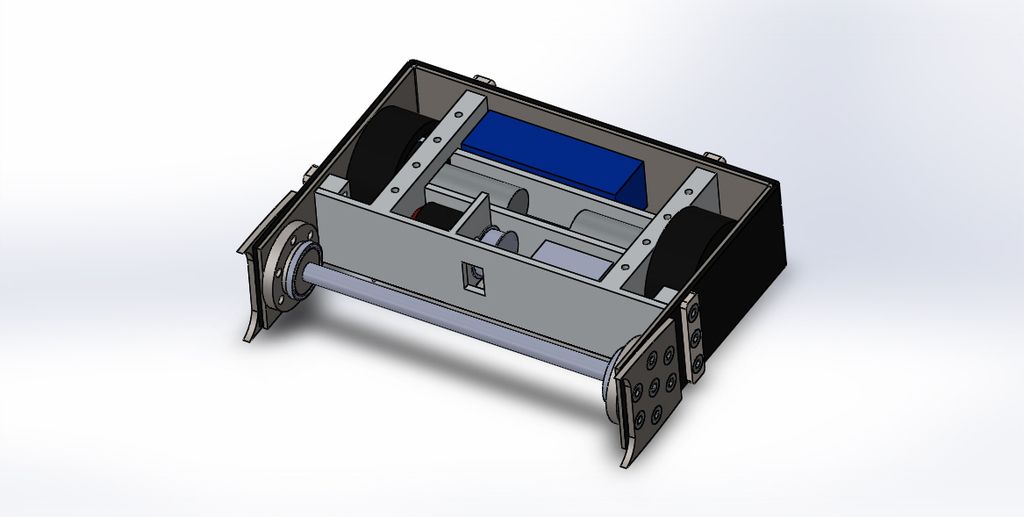

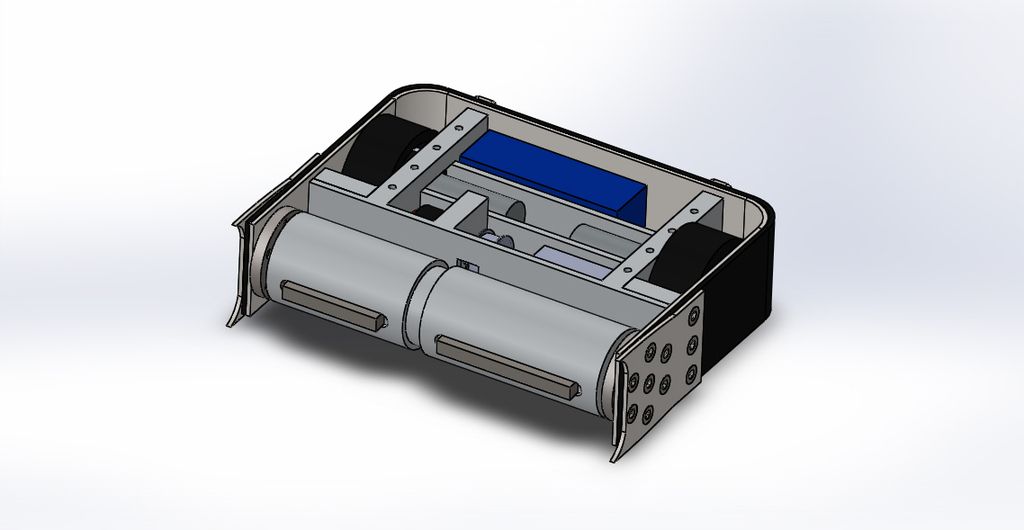

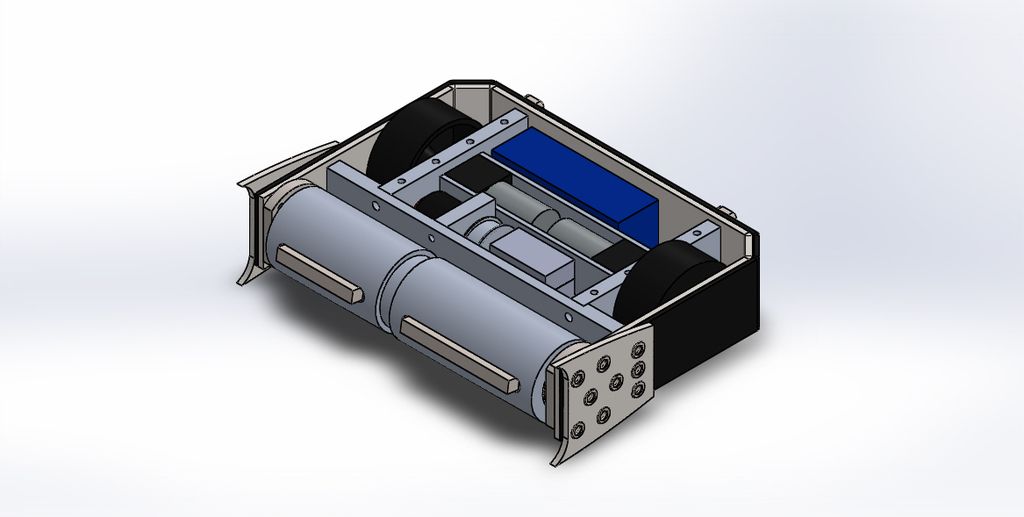

Firstly, nice CAD work, you're clearly comfortable in Solidworks!

The main question mark from what I see is the strength of the drum mounting. Looks like the shaft is dead which is good, but it seems a bit skinny otherwise. You have what, based on colour, is aluminium plate mounting the drives. Traditionally these would be brought forward and the drum would mount to them, in this case there is a slim (alu?) plate going across the front, which ties into the relatively thin (hardox or otherwise) sides, which then go forwards to support the drum.

Point is I think a hit from any good horizontal will badly deform the front, either by ripping a side out away from the drum or shunting them both sideways.

It's hard to strengthen that up without making use of the wheel bulkheads (which would also need thickening depending on grade), but then you get that nobody, mouldy or something they call him, accusing you of making a 720 clone. Number one key to success is don't listen to anything he says, ever.

It looks like you could save a good bit of weight if you reduced the chassis height? T3's internal height is just 50mm in order to squeeze the most out of the weight limit. Perhaps you can drop the height here so you can put weight back into other areas.

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 15:36.

Reply With Quote

Reply With Quote

Bookmarks