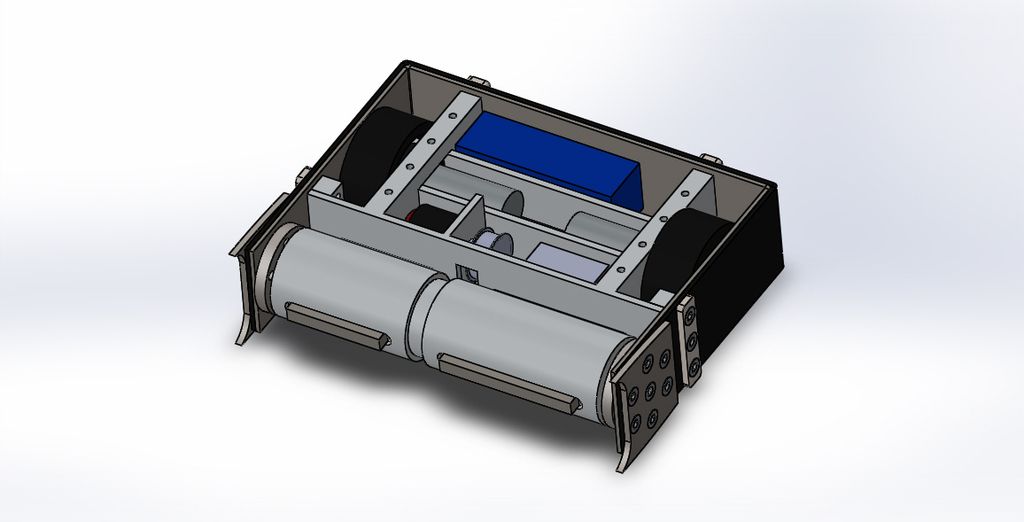

Also, couple of modifications made to the CAD:

Main changes are at the front the very front bits are removable so if they get bent I can swap them out and could try out a couple of different shapes for the front to find what works best for getting under people to bring them up into the drum. I've also got rid of the button head bolts and replaced them with countersunk bolts going into a strip of hardox which should mean they wont pull through the HDPE but also should be caught by vertical spinners but it does leave me more vulnerable to horizontal spinners.

But what I have realized was that I had misremembered the density of steel (argh) so all my mass calculations were wrong

So either I have to drop the Hardox down to 4mm with just those front bolt on pieces 6mm or get rid of the HDPE, front bolt on pieces and the hardox strips for the bolts (but these wouldn't be necessary anyway as I could countersink the hardox as the HDPE wouldn't be in the way) then I should just about be able to fit in the 6mm hardox.

Which do you guys think is preferable? The big issue with the 6mm hardox is that if the front wedge bits get bent out of shape there will be very little I can do about it other than replace the entire outer armour.

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 22:53.

Reply With Quote

Reply With Quote

Bookmarks