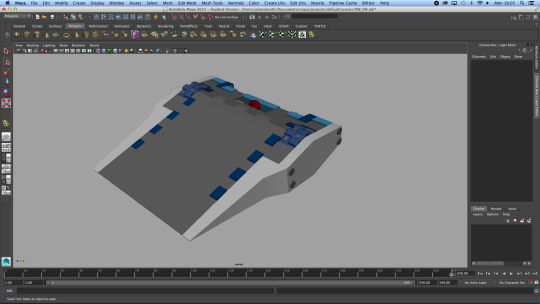

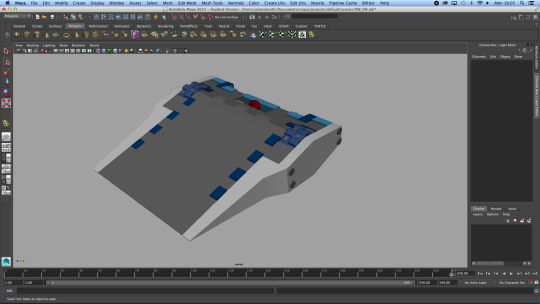

Something like this Alex?

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 08:24.

Something like this Alex?

The first is better. Alex is on about the same as i was, not presenting something for a spinner to chew on i.e a sharp edge.

some good feedback here thanks guys.

melted the nuts into the spare wheels and also sanded down the wheel ready for the tire tread.

Oh wow how did u melt the nuts in and where did you get them? I've not been brave enough to try yet lol. Is that a cheeky bit of gta going on there :P

I followed this guide by Ellis but without a pillar drill:

I used a old drill motor shaft fitted into a drill chuck and pressed the heated nut in.

I got my nuts here: http://www.ebay.co.uk/itm/1811604491...%3AMEBIDX%3AIT

They are 3/8 unf hex nuts.

yes I'm watching a lets play as I work.

Popped over to my local Halfords and got a bike tyre for tread to add to the wheels.

Considering you made them without a pillar drill, how much wobble do the wheels have? I was tempted to do this myself, but wasn't sure how well it'd turn out.

Bookmarks