I may put an even bigger motor in at some point so it saves me buying another esc, What robot are you using it in?

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 07:27.

I may put an even bigger motor in at some point so it saves me buying another esc, What robot are you using it in?

I'm using it in my own undercutter beetleweight. It will be bolted directly to a 200mm Bar.

Direct drive!? what voltage are you running that at? at 4s that would be something like 26,000 rpm! surely you're not that evil

Of course its 4S. I have Anvil to avenge! I am just that evil/crazy/mental.

In reality I won't floor the weapon unless I have too. Doing around 50% throttle will be more than enough. It just means that I can crank it up if the need arises. Or it may turn out to be nice and stable at 26'000rpm so I will just go straight there!

Last edited by Eventorizon; 26th September 2014 at 11:12.

Took a while to get this working but I finally managed it (turns out I had the low voltage cut off set wayyyyyy too high). Here's a nice little 3s spin up test of the black hole making motor http://vid921.photobucket.com/albums...ps1f83e92f.mp4

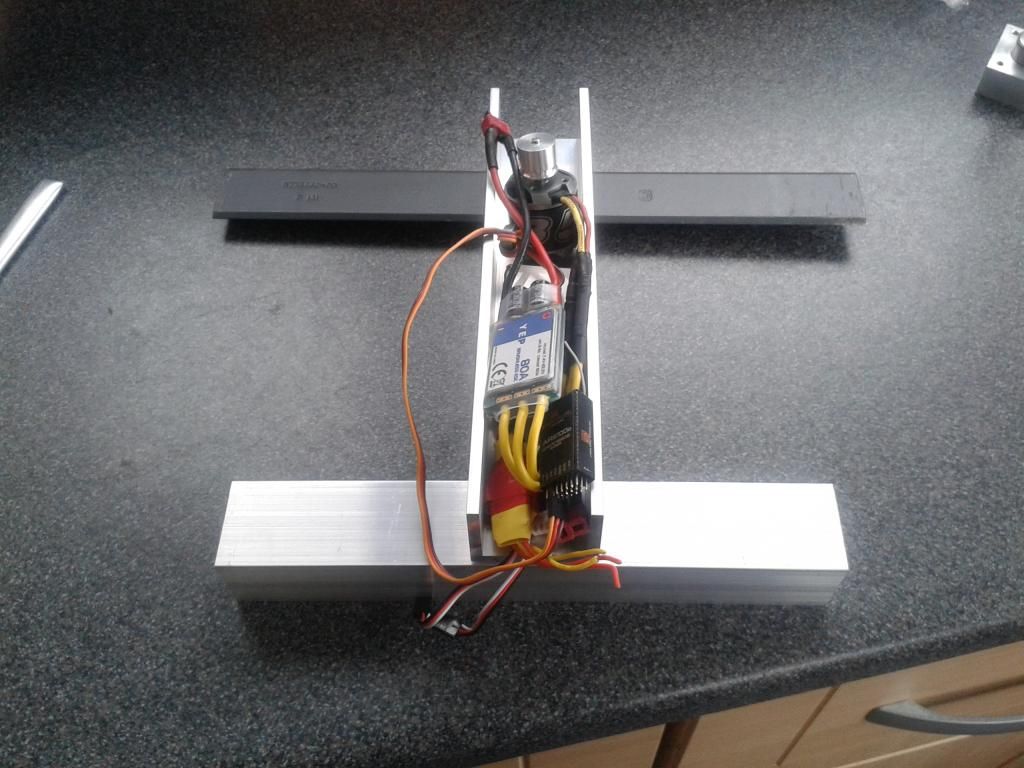

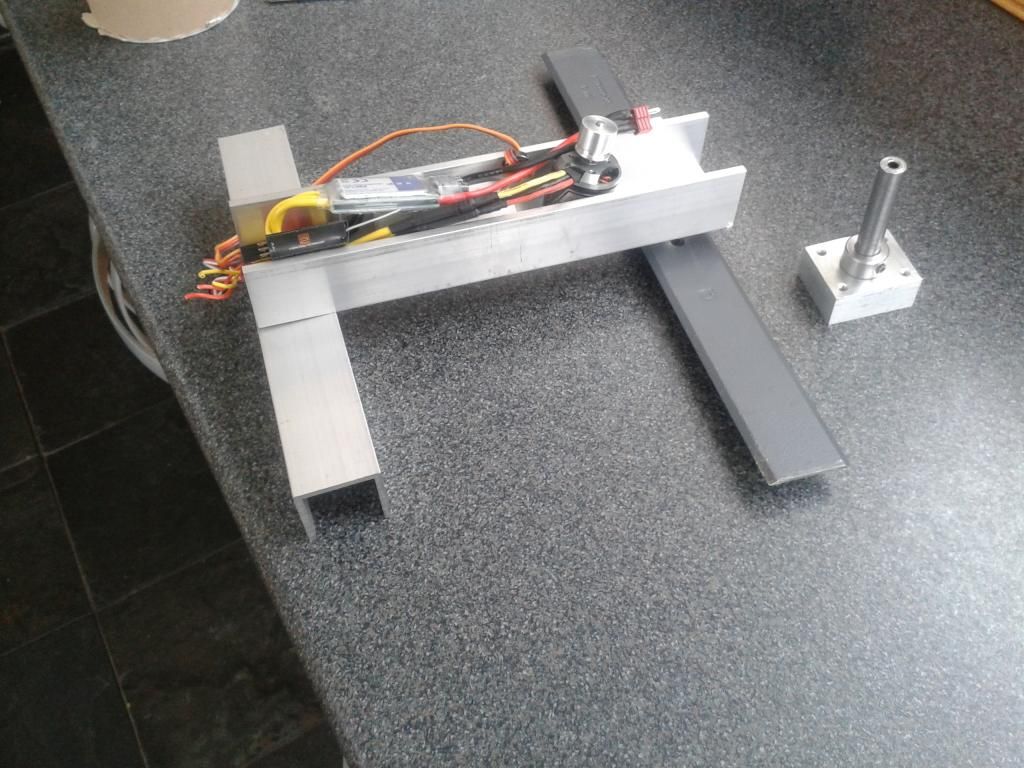

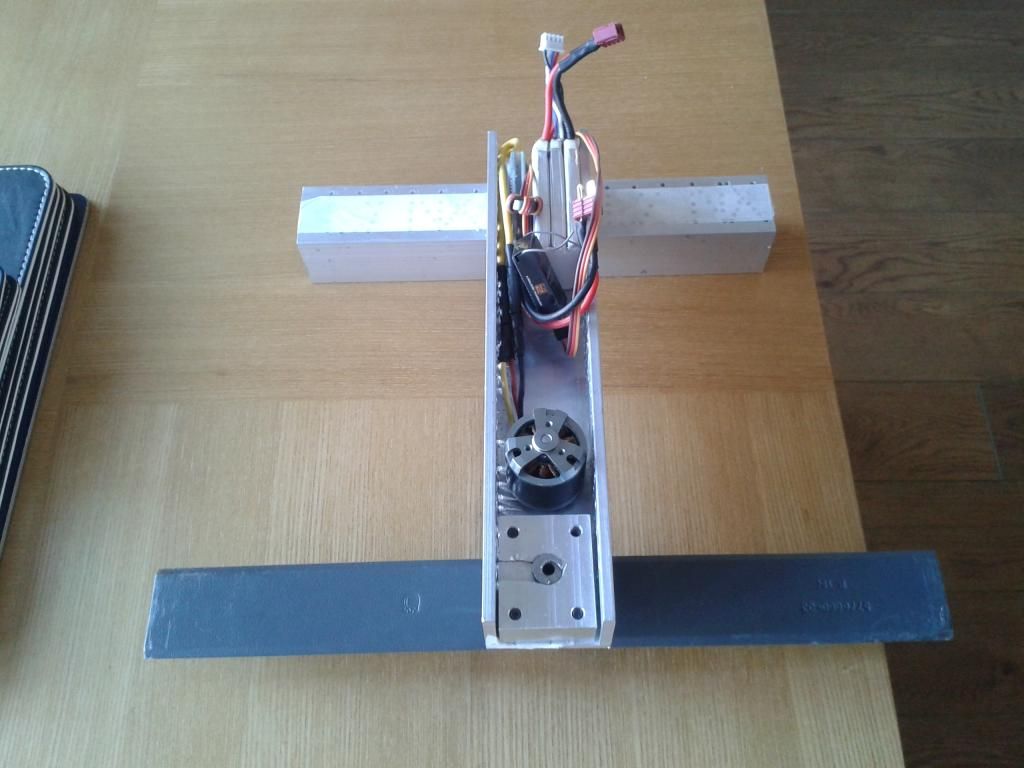

Been a while since I've posted on this thread but Lynx is finally underway, got everything but the drive motors and wheels so I have plenty to be getting on with. The chassis material is 6082 aluminium u channel ( 5mm thick for the main body and 3.5mm for the rear spar), I'm going to have to drill some weight out as it currently stands at 1.4kg, I think the last picture gives you an idea of how I'm going to lose the weight in style.

Been a while since I've worked on Lynx but I completely forgot to post the latest progress I made, without drive motors, mounts, armour etc it was coming in at just over 1.4kg which was a major worry so some drastic weight loss was in order. After much centre punching and about 2 hours worth of drilling I managed to remove around 120g and I still had one side of the frame to drill. Since then I haven't touched it I'm hoping my next day off will be just solid building. Couple of pics just to keep you interested.

And one more thing! Here's an entirely pointless test video of the weapon motor at 3s going to full throttle, for no other reason than it sounds like a freaking jet. http://vid921.photobucket.com/albums...psc0dlxhr9.mp4

BTW the noises in the background are my son.

Last edited by mrsam; 19th October 2014 at 10:03.

Not posted any progress on Lynx in a while but I've done a hufe amount of work on it the past couple of days. Everything is mounted bar the armour and drive set up ( still waiting on my Chinese gearmotors) and i've even found the cojones to do a full speed spin test. The ticking noise is the blade scraping the motor pulley slightly, it only does it sometimes but it's something I'm going to address, a thrust bearing between the body and blade should remove any up and down movement without hindering the spin up.

http://vid921.photobucket.com/albums...ps4mkqmyzy.mp4

What is keeping the bar off the ground? Is the shaft just spinning on the ground or it it tapered to a sharp point? And how much does it weigh at the moment... there can't be much left!

Its a dead shaft so it probably just has a locking collar then that runs on the floor.

Spin up is real good for such a massive weapon. Colour me impressed.

Bookmarks