Hi Guys

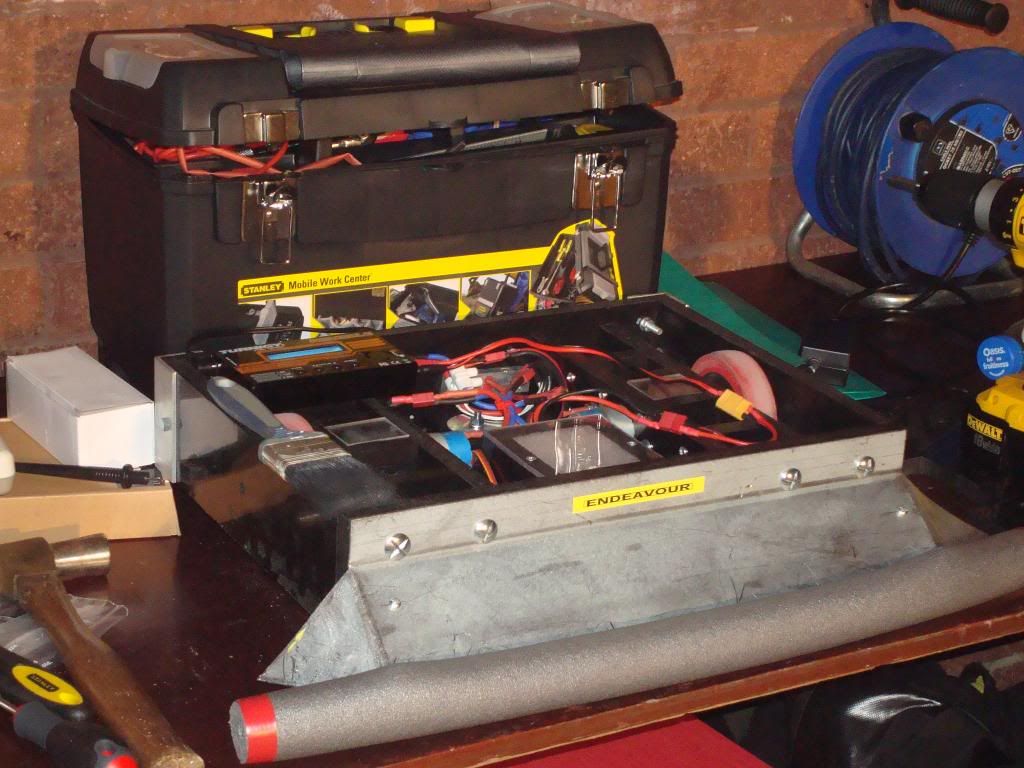

So, after its first outing at Portsmouth, I thought it was about time that I introduced you all to Endeavour properly. So......

Endeavour is my first ever combat robot and after studying rules and techniques, desiging and building for the past 2 or 3 years, I finaly made it into the arena. Here are the specs:

Name: Endeavour

Weght: Around 10Kg

Weapon: Rammer

Motors: Makita 14.4v drill motors

Batteries: 14.4v 5000 mAH

Size: 450mm x 330mm x 100mm

ESC: Bot Botz 85 amp

And some pics

Run down of Robot Wars Portsmouth 2013: We considered this event as a test run for the FW champs. In the first two fights, the robot felt abit sluggish campared to the night before when we were testing. We later found out that this was due to the transmitter being in low rate mode. A school boy mistake, but at least we made it at Portsmouth, not Birmingham when we are fighting 720. The main problem we had at this event was the scoop bending. This happened in almost every fight which caused us to lose drive. The reason it bent was because it was made out of 2mm mild steel. In the next few weeks we are going to get another one made in 4mm steel with support on the side flaps. All in all, i think that it was a great shake down for the bot and it was a great experince.

Will put some photos up of the build process adn the really bent scoop when I get a chance.

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 04:09.

Reply With Quote

Reply With Quote

Bookmarks