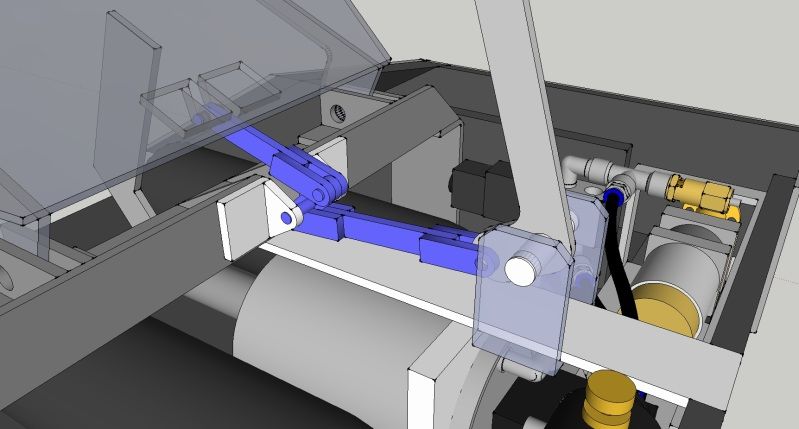

Ah recognised the Sabertooth :wink: I got the 2x60 in there, I know its not highly recommended but we've used it with no issues last November... fingers crossed!!

Yes that L shaped piece is there because I got a piece of titanium in a roughly similar shape and thought I'd use it but triangular shape would be a better bet - will re design!

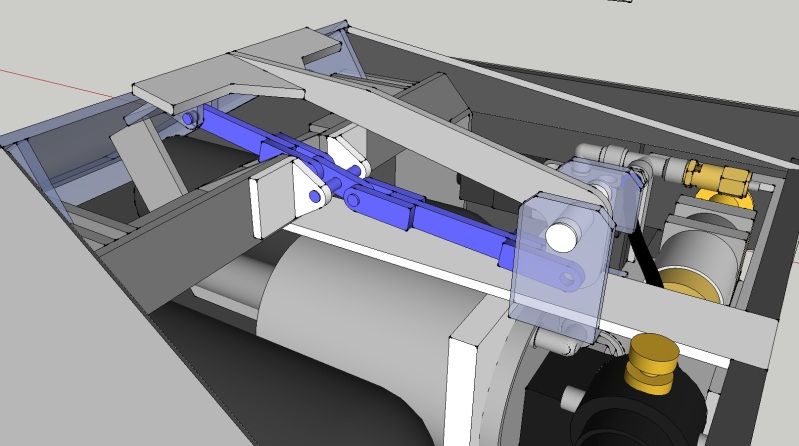

Drive is still a question mark, I had tracks on it and maneuverability was top notch, the down side was the added weight and less grip. I might go the 4WD way like you said or tracks again - both are possible in the available space.

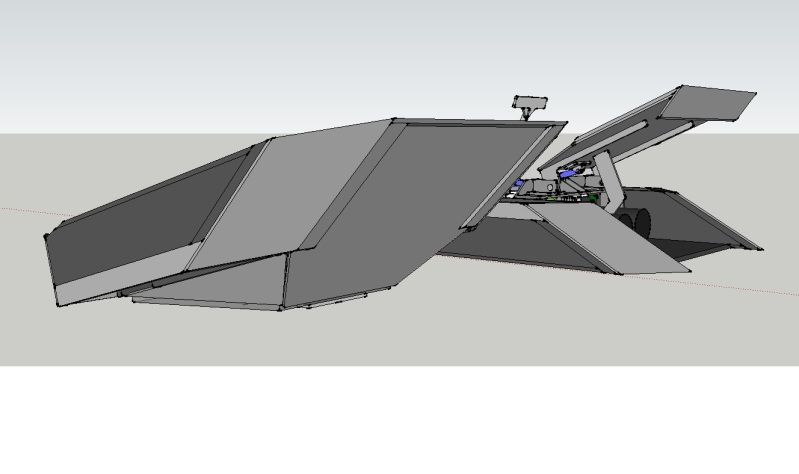

Yes the wedge shape really looks like a stealth something - keeping it as low as possible - the highest point is just 160mm!

Thanks for the encouragement hope to make it to an event in the Uk next year

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 11:04.

Reply With Quote

Reply With Quote

Bookmarks