Seeing as Matt decided to put all of his robot builds into one thread i figured i'd do the same, bit of a weird team scenario we have going on here with two different build diaries but it would be way too complicated with the umpteen amount of robots we have between us.

So on to the robots, i never really bothered with a post champs report and it seems a little late now, having said that i'm eager to get on with some updates instead of taking a break like i said i would.

Hatchet performed so much better at the World champs than i thought and i think it surprised quite a few of you as well, despite taking on 8 different spinners over the weekend it took no significant damage, took a few huge hits from NST but even that was easily repairable. So as it stands i can still use the current machine at some live events until i rebuild it, sticking with all of the same internal components as i was really happy with the weapon and drive but changing the chassis design slightly.

I was much happier with the chassis this time around, the thicker hdpe and the addition of barrel buts really helped with strength. Having said that the top panel was pitiful due to weight reasons and the body was so tall that there was a huge amount weight tied up in empty space. A few changes are definitely in order then, i'm actually going to look at Hatchet 1 for inspiration here, the old machine had the side panels bolted to the baseplate and the front and rear panels overhanging so they were flush with the base of the machine.

I like this design better, it gives me a little more space inside, means i can make the machine sorter and also makes the baseplate and lid flush with the front and real panels. I had a few times at the champs where the lid was caught and peeled back so hopefully that doesn't happen again. I'm also going to make the chassis from a mix of 15 and 20mm hdpe, the rear and side panels took no damage at all this year so they will be made from 15, the front panel, wheel guards and axe bulkheads will stay 20mm thick although i will be drilling a few holes in the axe bulkheads to remove a bit of weight. All of this means that i can afford to have a thicker lid and hopefully fit the Aluminium bracing to the rear corners.

My final update will please some of you in particular (Dave Weston), as happy as i was with the axe this year i wasn't all that pleased with the damage (or lack of) that it caused, especially to hdpe. Seeing as i have a double sided axe with a nice pointy end i'm going to be fitting a second 8mm sprocket to the other side of the axe shaft. This means that i can alternate between pointy and broad heads depending on the opponent, it also means that any of you with suspect top panels had better hope you don't meet Hatchet next year.

If you managed to sit through all of that well done, I'll be keeping this thread updated regularly with progress on Hatchet and the rebuild of my beetleweight spinner Lynx.

- FRA

- Forum

- Robots

- Events

- Media

- What's New?

All times are GMT. The time now is 07:32.

Reply With Quote

Reply With Quote

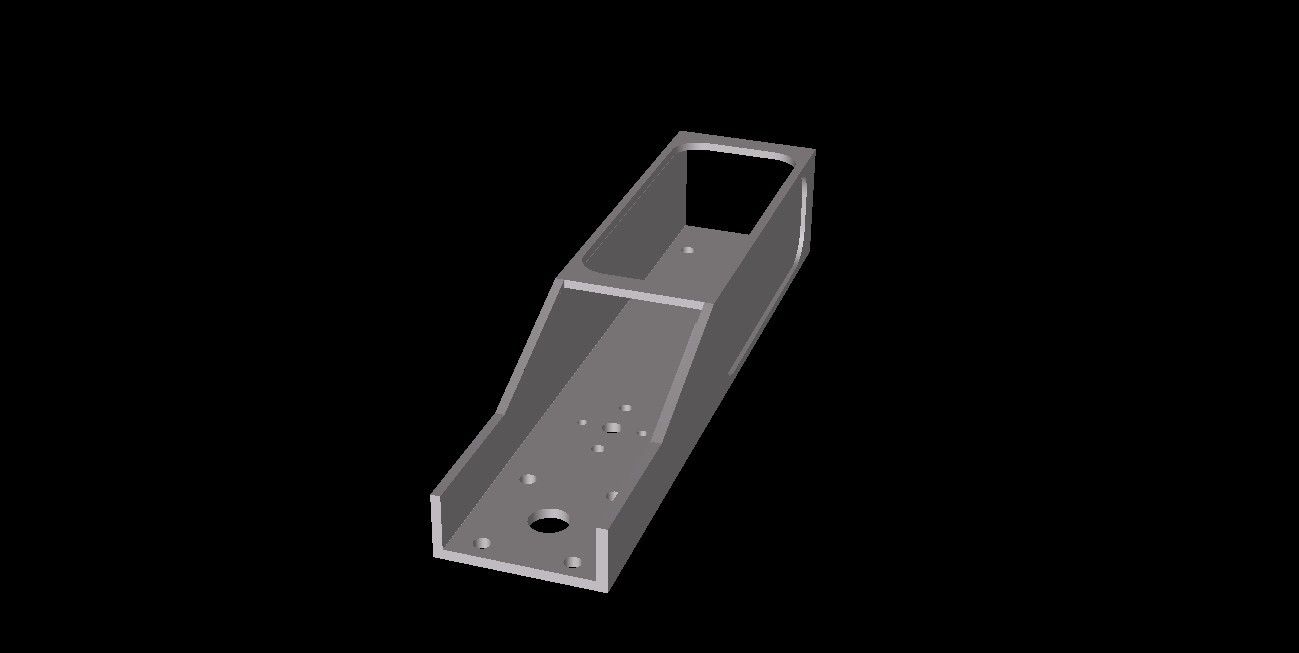

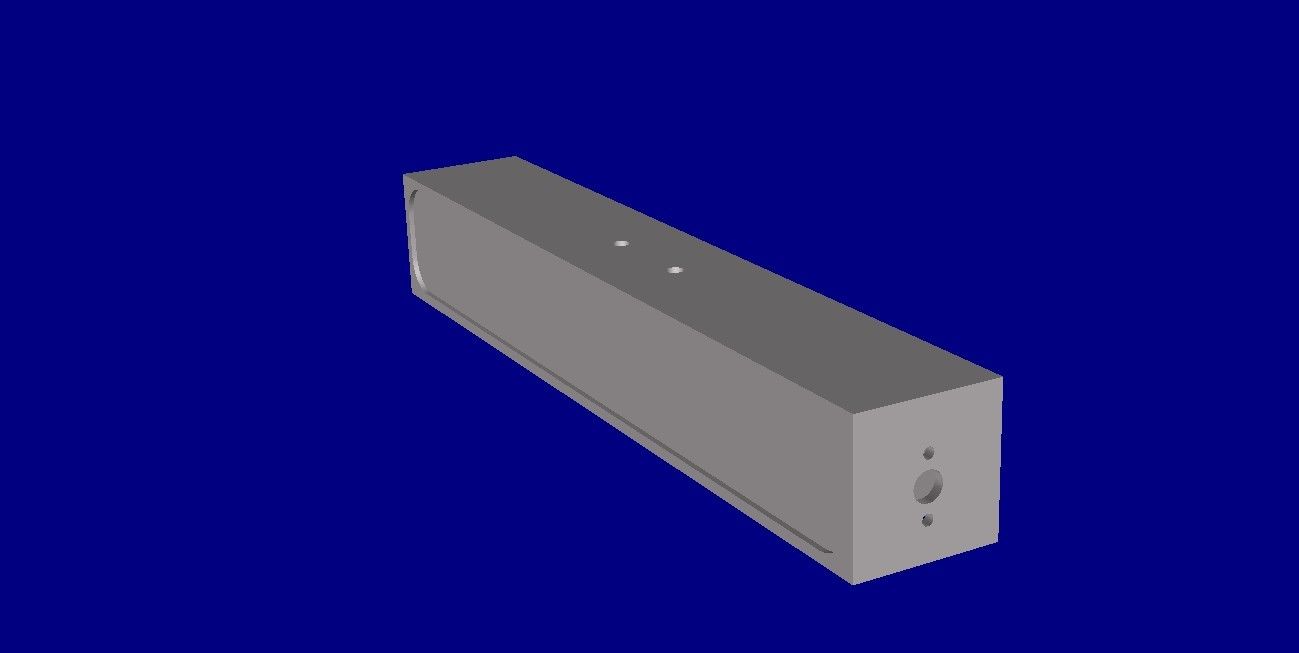

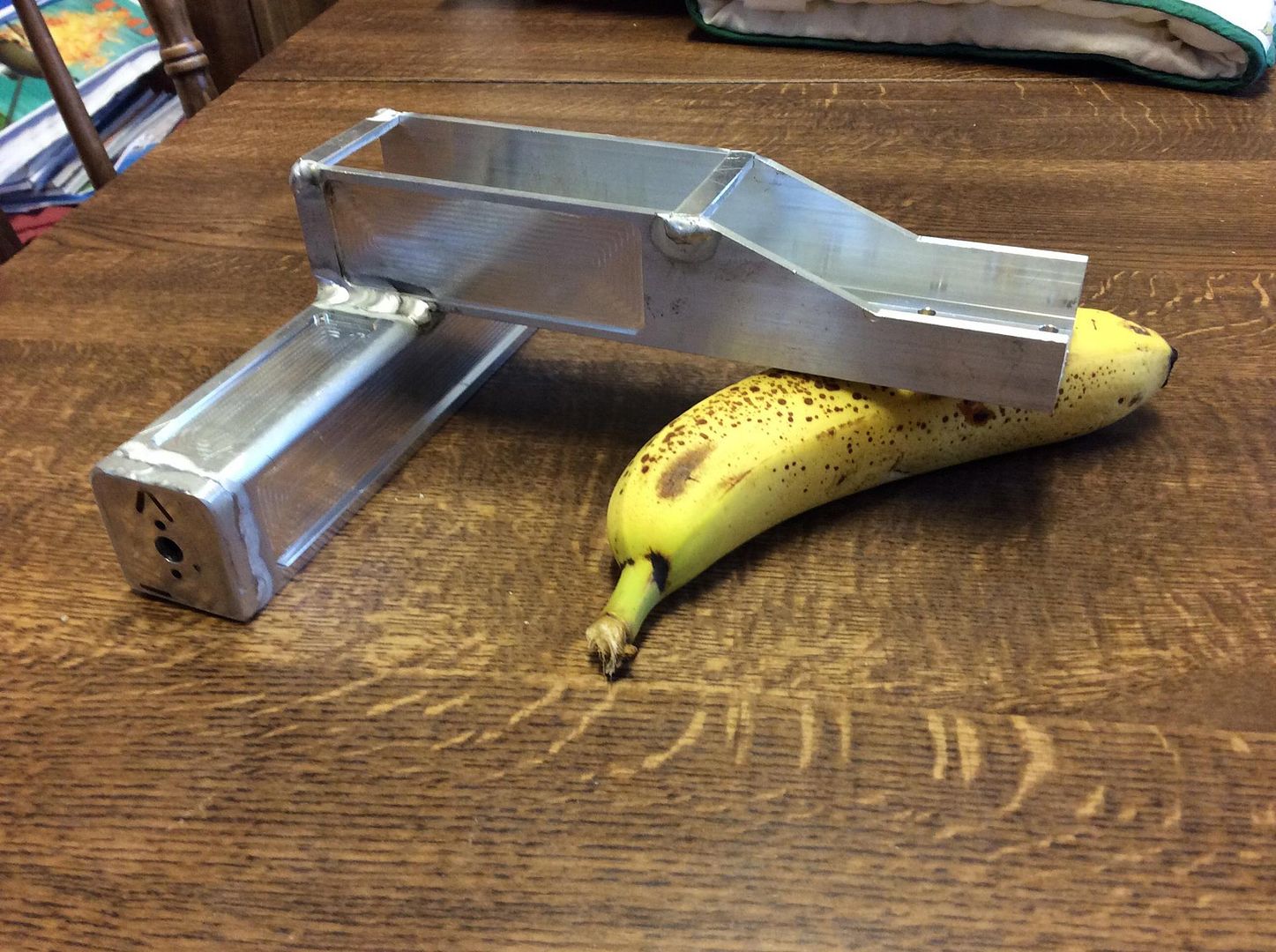

As you can see, much better than it was before. It's the same grade Aluminium ( 3mm 6082 T6) but it has 1.5mm deep pockets to keep the weight down whilst keeping the structural strength in the frame, it also has thicker drive motor mounts and it's all been welded into one single piece which means a) it's stronger and b) i can save weight by not having bolts.

As you can see, much better than it was before. It's the same grade Aluminium ( 3mm 6082 T6) but it has 1.5mm deep pockets to keep the weight down whilst keeping the structural strength in the frame, it also has thicker drive motor mounts and it's all been welded into one single piece which means a) it's stronger and b) i can save weight by not having bolts.

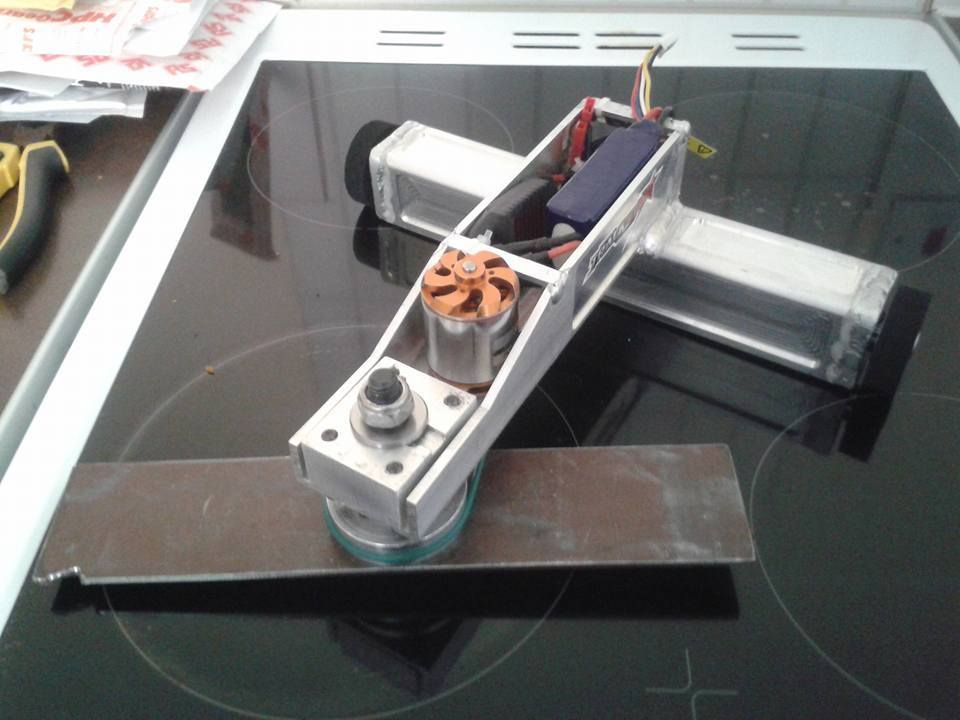

I didn't take many pictures throughout the build so we've skipped to a nearly finished robot, you can see the new brushless set up and frame and how everything kind of...fits? Wait wait....things fit in Lynx? what kind of sorcery is this?

I didn't take many pictures throughout the build so we've skipped to a nearly finished robot, you can see the new brushless set up and frame and how everything kind of...fits? Wait wait....things fit in Lynx? what kind of sorcery is this? So, that's the new Lynx, well done if you managed to sit through and read all of that. It'll be Debuting at the Kinematic event in Scotland on the 6th of August where i'm hoping the upgrades will mean it does well.

So, that's the new Lynx, well done if you managed to sit through and read all of that. It'll be Debuting at the Kinematic event in Scotland on the 6th of August where i'm hoping the upgrades will mean it does well.

Bookmarks